3D Printing

Elon Musk is trying to make the human race inter-planetary and to achieve that goal he needs to transport millions of tons of material(Food, Shelter, and Scientific necessities) to the planet where life is possible.To make it possible he have two options :

- Carrying that whole load on a spaceship which makes the travel inefficent.

- Using the technology of additive manufacturing or 3D printing.

What is 3D Printing

3D Printing or additive manufacturing is a technique to create a three-dimensional model using a CAD model or a 3D model, typically in a layer-by-layer manner under the control of Computer Numerical Control (CNC).

3D Printing Technology was invented by Chuck Hull in 1986. He is also the inventor of the STL 3D oninter which is the first commercial 3D printer in the market.

Why 3D Printing ?

Imagine to build a prototype of wooden house with naked hands then first you will bring the raw materia l (wooden block) and then perfect tools (Handsaw,sanders) on the table and further you process and Boom you come with a nice wooden house prototype but there are few problems that you may encounter:

- What if the design is so complex that it seems impossible to construct it with hands.

- What if the profession doesn't require an outcome?

- Traditional way repeatability requires t,, t,,,,ime.

3D Printing delivers repeatabilty,precision and range that’s why it is extensively used to construct complex models which would be impossible with naked hands.

How 3D Printer Works?

3D Printer works the same as an inept printer instead of spraying the ink on the bottom-up it builds a 3D model layer by layer in a bottom-up approach, by repeatedly printing over the same modeling method known as fused depostional modelling (FDM). A 3D Printer primarily works by extrudingishe the molten plastics through a tiny nozzle whether ich in a predetermined path under the control of computer.

The 3D Printer works as follows:

- 3D Printer converts the 3D CAD model into lots of 2D,cross sectional layers – effectively separate 2D prints which will sit one on top of another.

- The Printer deposits a layer of molten thermoplastics and fuse them with the adhesive or ultraviolet light

Types of Material and Technologies in 3D Printing

The most challenging part that an engineer and designer face while entering this field is what type of material and technology is suitable for their application because the different application has different material with different properties and different technologies somehow bring variation in properties like dimensional accuracy, final finishing, and post-processing requirements.

3D printing Material Group

3D Printing material Group is mainly classified into two subgroups — Polymers and Metals. Now let’s jump into it:

Polymers

Polymers are everywhere around us from the tip of the toothbrush to the covering rocket body. Polymer provides diversity in properties and form which makes it suitable for different applications. A polymer such as plastic is generally used for the purpose of 3D printing—

- Thermoplastics

These plastics can melt and solidifies again and again without losing their properties.

Traditional injecting, molding as well as FFF process uses thermoplastics.

Thermosets

These plastics don’t melt after solidification.

The SLA/DLP and the material jetting process use the photopolymer plastic that hardens when kept under laser or UV light.

Metal

Metal 3D printing exclusively uses metallic powders to produce high-quality, functional, and load-bearing mechanical parts of a system. The properties of metallic powder that govern whether the metal powder is suitable or not are Particle size, and flowability.

What is Metal 3D Printing?

Metal 3D Printing is a cutting-edge technology to bring the most suitable mechanical part of a machine or a system with the help of powdered metal and a Laser.

Metal 3D Printing uses the technology of Power Bed fusion to produce the solid parts, using a thermal source (laser or electron beam) to induce fusion between powder metal particles one layer at a time.

Based on the thermal source there are two variations in the Powder Bed Fusion Technology:

Based on Electron Beam, there is a technology called Electron beam melting (EBM).

Electron Beam Melting (EBM) uses a high-energy beam (electrons) rather than a laser (photons) to induce fusion between the particles of metal powder.

A focused electron beam scans across a thin layer of powder, causing localized melting and solidification over a specific cross-sectional area. These layers are built up to create a solid part.

EBM is generally faster as compared to the DMLS/SMLS because of its high energy density.

Application of Metal 3D Printing

DMLS/SMLS is best suited for the application where we require the end result which has a complex structure and geometry to build, with naked hand or traditional manufacturing.

Some of the Real-life applications using Metal 3D printing are as follows:

- Dental applications

DMLS/SLM has become a popular option in the dental industry with the direct metal printing of crowns and bridges now commonplace. It reduces the lead time of investment casting while the ability to print hundreds of custom parts in a single shot accelerates the production

Medical applications

The medical industry has embraced metal 3D printing. Virtually any design can be printed to exactly fit a patient’s anatomy and can be made to include unique surface characteristics (like porosity) to encourage bone growth and improve patient outcomes

Aerospace

Aerospace and automotive are industries where lightweight parts are a critical design parameter. DMLS/SMLS is an ideal solution to achieve this parameter. DMLS/SMLS allows manufacturing the complex geometries which were very expensive or impossible to manufacture. The production of parts is done with high-strength and high-performance metals (like titanium or aluminum alloys).

Best 3D Printer to Buy in 2022

Some decades ago 3D printers were only available in big manufacturing houses and they were damn costly. But now as technology evolved 3D printers are available at educational institutes and many designer's offices. As the demand for 3D Printing increases so here are a few 3D that you can buy as per your need:

| Image | Product | Feature | Price |

|---|---|---|---|

|

TOP Pick

|

Creality Ender 6 3D Printer

|

Higher Precision and Quick Printing Speed | Ultra Silent TMC2208 Chip | Buy Now |

|

Trending

|

Anycubic Photon Mono

|

4K High Speed Resin 3D Printer with 6.23" Monochrome Screen 3D Printer | Buy Now |

|

TOP Pick

|

3idea Flashforge Creator 2

|

Industrial Independent Dual Extruder 3D Printer 3D Printer | Buy Now |

|

Trending

|

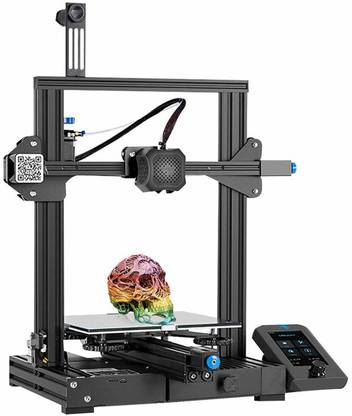

Creality Ender-3 V2 2021 FDM

|

Silent Motherboard Meanwell Power Supply | Carborundum Glass Platform | Resume Printing | Color Display | 3D Printer | Buy Now |

FAQs

Many of the readers have many out-of-the-box questions in their minds which they can ask me in the comment section or they can contact me via mail. But some Frequently asked questions are as follows on this topic:

What are 3D printed shoes made of?

Ans:- A shoe should be durable and lightweight that’s why the best choice nowadays to make 3D printed shoes is Thermoplastic polyurethane.

What is 3D printing in forensics?

Ans:- 3D printing in forensics can be used in the following ways:

Facial recognition

Human Identification

Pattern Analysis

Disaster victim identification

How can 3D printing technology help medical conditions?

Ans:- With the use of bioprinters it is easy to replicate the tissue with living cells, without the use of plastic and metal. It also helps doctors to perform training on some tough medical procedures.

I just hope you find this blog helpful and if yes then please share with your more curious friends on social media. Just tell me where I can improve in the comment section.

0 Comments

THANK YOU